ChevyParts

My Garage

My Account

Cart

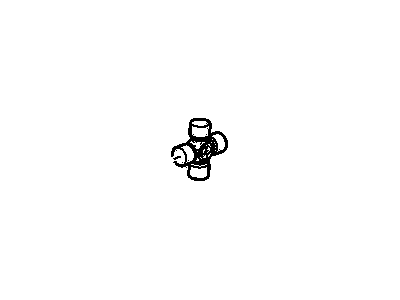

OEM Chevrolet Suburban 1500 Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Universal Joints found

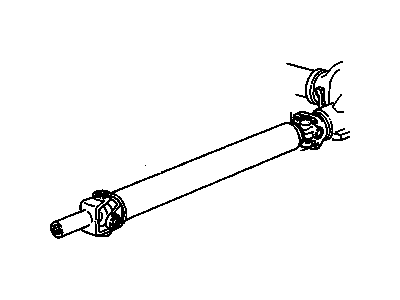

Chevrolet Suburban 1500 Universal Joints Part Number: 23104840

$36.45 MSRP: $88.98You Save: $52.53 (60%)

Chevrolet Suburban 1500 Universal Joints Part Number: 89059111

$163.83 MSRP: $273.43You Save: $109.60 (41%)Ships in 1-2 Business Days

Chevrolet Suburban 1500 Universal Joints Part Number: 89040245

$107.41 MSRP: $180.82You Save: $73.41 (41%)Ships in 1-2 Business Days

Chevrolet Suburban 1500 Universal Joints Part Number: 89040243

$112.32 MSRP: $189.10You Save: $76.78 (41%)Ships in 1-2 Business Days

Chevrolet Suburban 1500 Universal Joints Part Number: 88964413

$196.62 MSRP: $328.19You Save: $131.57 (41%)Ships in 1-2 Business Days

Chevrolet Suburban 1500 Universal Joint

Want to cut long-term maintenance and repair costs? Choose OEM Universal Joint. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Suburban 1500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Suburban 1500 Universal Joint includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Suburban 1500 Universal Joint Parts and Q&A

- Q: How to replace the universal joint with a nylon injected ring on Chevrolet Suburban 1500?A:To switch to a nylon injected ring for the Universal Joint collect these parts first: u-joint bearing separator (J9522-3) and u-joint bearing spacer remover (J9522-5). Place the propeller shaft horizontally under light pressure without clamping the tubing inside the vise because it may harm the components. Draw markings to confirm the right attitude of the propeller shaft. Set the Universal Joint on top of the 30 mm (11 1/8 inch) socket so that only the lower yoke ear contacts the socket. Press the lower bearing cup out of the yoke ear through the u-joint bearing separator tool j9522-3 which shears the plastic retaining ring on the bearing cup. Push the u-joint bearing spacer remover (J9522-5) beyond the seal to extract the bearing cup when manual force fails to free it. Mark the Slip Yoke position before removing its opposite bearing cup using the propeller shaft rotation. Uninstall the cross and leftover joint elements to check for debris or damage around the retaining ring grooves and bearing cup bores. Take out remaining plastic pieces from the groove spaces to get optimal positioning of the new bearing cups. To assemble the items place one bearing cup partially into one side of the yoke before you place the yoke ear down then interact the cross with caution to permit the trunnion to move without difficulty. Stick the bearing cup to its yoke ear mark without touching the other side. Do this with both bearing cups as you line up their trunnions perfectly. Check how well the needle bearings line up to find the source of the binding. Push down firmly until the bearing retainer slot shows through before fitting the retainer and pressing both pieces into their correct positions. Use a dead blow hammer as needed while pushing the retainer into position. Also apply chassis grease to the snap ring to lower installation challenges.

- Q: What tools are needed to service and repair the universal joint with a nylon injected ring on Chevrolet Suburban 1500?A:Repair or service the universal joint containing a nylon ring by using tool set J 9522-3 and J 9522-5. Two necessary tools include U Joint Bearing Separator (J 9522-3) and U Joint Bearing Spacer Remover (J 9522-5). The first step should include supporting the propeller shaft horizontally on a press but avoid clamping the tubing in a vise because this could cause damage. Record clear markings at both ends of the propeller shaft to maintain the correct orientation. Set the universal joint within the lower yoke ear on a 30 mm (1 1/8 inch) socket. Proceed by using the U Joint Bearing Separator (J 9522-3) to divide the plastic retaining ring on the bearing cup before pressing the lower bearing cup out of the yoke ear. The U Joint Bearing Spacer Remover (J 9522-5) allows users to press out remaining bearing cups by placing it between the seal and the cup. The propeller shaft rotation will force the opposite bearing cup to exit before removing the cross piece as well as any leftover universal joint elements. Check the retaining ring grooves together with bearing cup bores for any signs of damage before cleaning them both. To assemble the yoke you must first drive a bearing cup into one yoke side while you position the cross to accept the trunnion without restriction. Pressibrate the bearing cup until it fully masters the yoke ear then perform these steps for the other side making sure trunnions maintain correct alignment. Check the needle bearings for misalignment in case binding takes place. Use the press tool to drive the bearing retainer groove out of the yoke before installing the retainer snap ring. A dead blow hammer can help you set the retainer correctly if required. Application of chassis grease to the snap ring may help its correct positioning within the bearing cup groove.